Design of New Vertical Shaft Type Windmills

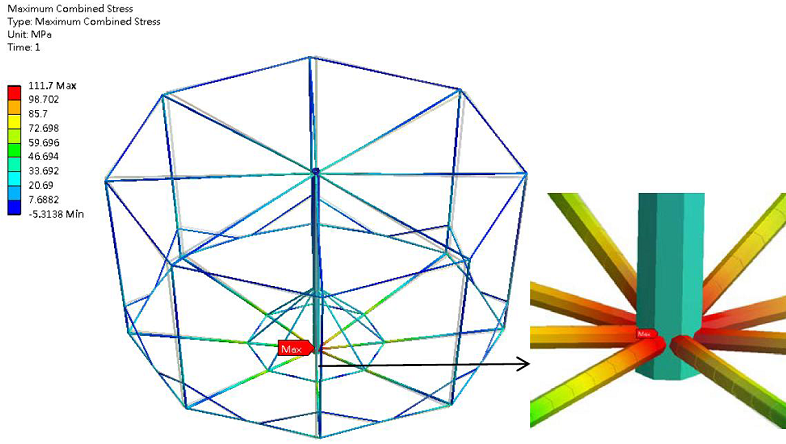

The present study is to extend the results of “Vertical shaft-type wind-power Chinese square-pallet chain-pumps” by “learning new things through a review of existed knowledge” and then making use of the unique design of the Chinese windmill to create an innovative design of windmills. Firstly, according to the results of the configuration, motion and structural analyses of the Chinese windmill, the design standards of new vertical-shaft windmills were set up. The windmill structures are mainly composed of metal materials and should be operated safely under a wind speed of 12m/s. Their sails can be easily and quicklydismantled or replaced and don’t need a bowline to control the limit positions of sail. Secondly, in the innovative design, the solid models of windmills were built using the graphic software SolidWorks and two new types of vertical-shaft windmills were obtained. Type 1 of the windmills was built by adopting the structural design of the Chinese vertical-shaft windmill. As for its limiting devices for sails, two limit positions were determined through the integrated operation of a screw mechanism and a limiting pole. Type 2 was also built by referring to the structural design of the Chinese windmill. It was applicable to multi-layer structural design and cleverly made use of the windmill structure to determine the limit positions of sail. Because a shorter converting time of sail between the two limit positions could increase the output torque of the windmill, a light honeycomb panel with high strength was adopted as the material of sail. In order to facilitate the installation and maintenance of the sail, a fast-dismantling device equipped with a universal joint was adopted as the joint of sail so as to reduce the time for dismantling or replacing the sail. Moreover, in order to analyze the structural strengths of Type 1 and Type 2, the present study made useof the finite element software ANSYS Workbench to perform the simulations of the static structure for the windmills under wind loads. According to the results of analyses, it shows that their safety factors are above 2.21 even though the windmills are operated under a wind speed of 12m/s and then their structural strengths meet the requirements of design standards. Finally, the two new vertical-shafted windmills created in the present study can combine with a pumping device to form a new wind-powered waterpump, serve as a power unit for other systems, or even develop a new device of wind power generation. It not only allows the Chinese vertical-shaft windmill to create a new modern meaning but also realizes the integration of culture, science and technology.